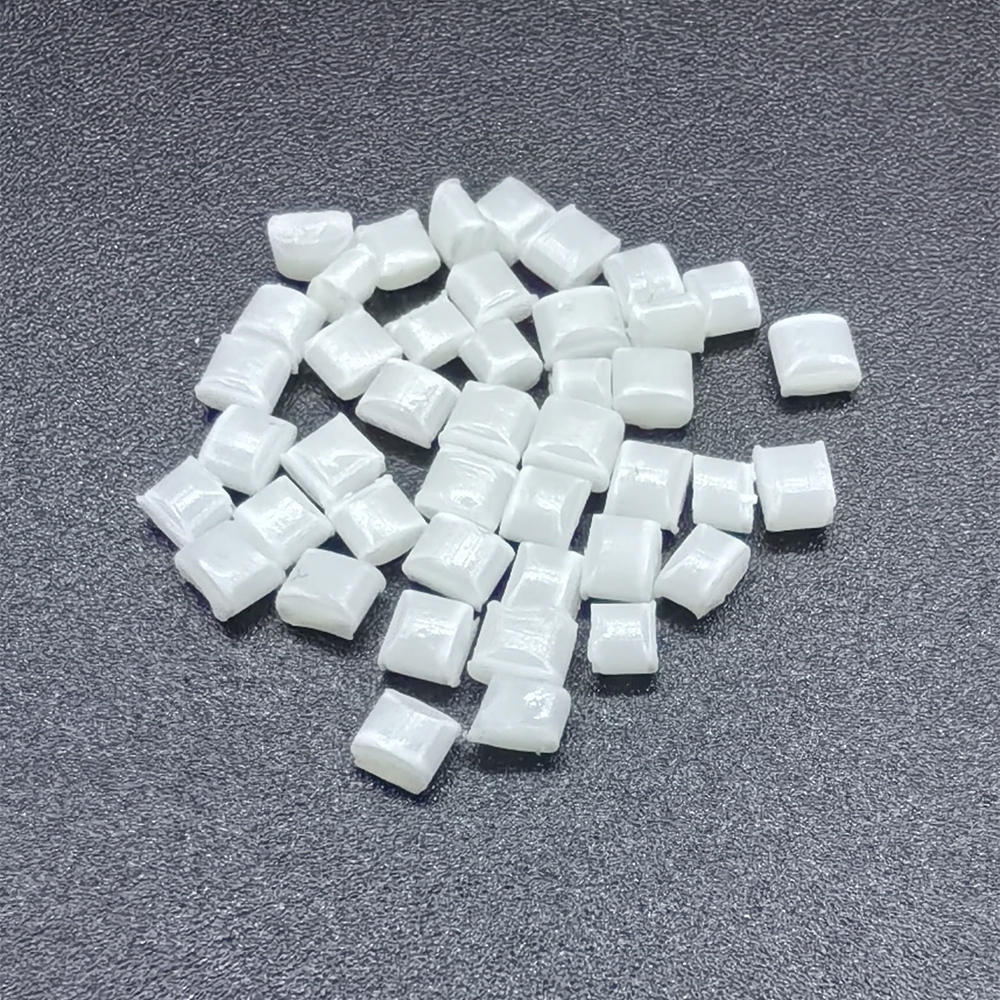

ABS AE10EP

Types:ABS

Model:ABS AE10EP

Manufacturer:25KG/Bag

Specification:Formosa Chemicals & Fibre Corporation

Color:Natural / Black

Shipping Location:Dongguan City, Guangdong Province, China

Email:Max@abs-Plastic.com

Phone:86+ 13790282186

WeChat:13790282186

Click me to view prices

Introduction to ABS AE10EP: Properties and Applications

Acrylonitrile Butadiene Styrene (ABS) is one of the most widely used engineering plastics due to its excellent balance of strength, impact resistance, and processability. ABS AE10EP is a specialized grade that offers enhanced properties for specific applications. This article provides a comprehensive introduction to ABS AE10EP, focusing on its key performance characteristics and typical applic

Performance Characteristics of ABS AE10EP

ABS AE10EP possesses a unique set of physical, mechanical, and chemical properties that make it stand out among standard ABS grades. Here are some of its key

1. High Impact Resistance

One of the most significant advantages of ABS AE10EP is its superior impact strength. The material has been engineered to withstand sudden forces without cracking or breaking, making it ideal for applications that require durability and toughness. This characteristic is particularly beneficial in products exposed to mechanical s

2. Excellent Processability

ABS AE10EP exhibits excellent processability, making it suitable for injection molding and extrusion. It has a stable melt flow rate, allowing manufacturers to produce complex shapes with high precision. The material’s good dimensional stability ensures minimal shrinkage and warping during processing, contributing to consistent

3. Enhanced Heat Resistance

Compared to standard ABS grades, AE10EP has improved heat resistance, allowing it to perform well under moderate to high-temperature conditions. This makes it a suitable choice for applications where exposure to heat is a concern, such as electronic enclosures and a

4. Chemical Resistance

ABS AE10EP offers good resistance to chemicals such as acids, alkalis, and oils. This property makes it valuable in industries where exposure to harsh substances is common, including automotive, electronics, and industrial equipment manufacturing.

5. Excellent Surface Finish and Paintability

The material has a smooth surface finish, which enhances its aesthetic appeal. Additionally, it has good adhesion properties, allowing for easy painting, plating, or printing. This feature is especially important for consumer products that require a high-quality appearance.

6. Balanced Strength and Stiffness

ABS AE10EP provides a well-balanced combination of strength and rigidity. While it maintains flexibility to absorb impact, it also has sufficient stiffness to retain its shape under mechanical stress. This makes it an excellent choice for structural components and load-bearing applications.

Applications of ABS AE10EP

Thanks to its outstanding performance characteristics, ABS AE10EP is widely used across various industries. Below are some of the key applications where this material excels.

1. Automotive Industry

ABS AE10EP is a preferred material in the automotive sector due to its high impact strength and heat resistance. It is commonly used in:

- Interior and exterior trim parts

- Dashboard panels

- Bumper reinforcements

- Door panels and handles

- Air vents and console components

The material’s ability to withstand mechanical stress and environmental conditions makes it ideal for automotive applications that require both durability and aesthetic appeal.

2. Electrical and Electronics

The electronics industry benefits significantly from ABS AE10EP’s good electrical insulation properties and heat resistance. It is widely used in:

- Electrical enclosures and housings

- Battery cases

- Connectors and sockets

- Laptop and mobile phone casings

These applications require a material that can protect sensitive electronic components while offering good processability for complex designs.

3. Consumer Goods

ABS AE10EP is commonly found in consumer products due to its superior surface finish and durability. Common applications include:

- Home appliances such as vacuum cleaner parts and washing machine panels

- Toys and gaming accessories

- Luggage and protective cases

- Sporting goods such as helmets and protective gear

Its ability to maintain an attractive appearance while being strong and impact-resistant makes it an excellent choice for consumer-oriented applications.

4. Industrial Equipment

Many industrial applications require materials that can withstand mechanical stress and exposure to chemicals. ABS AE10EP is used in:

- Machine housings and covers

- Tool handles and grips

- Conveyor system components

- Storage containers for chemicals and tools

The material’s resistance to chemicals and impact ensures long-lasting performance in demanding industrial environments.

5. Medical Equipment

ABS AE10EP is also used in the medical field for non-implantable applications such as:

- Medical device casings

- Laboratory equipment housings

- Diagnostic tool enclosures

Its chemical resistance and ease of sterilization make it a suitable material for medical applications that require cleanliness and durability.

Conclusion

ABS AE10EP is a high-performance ABS grade that offers an excellent balance of impact resistance, heat resistance, chemical resistance, and aesthetic appeal. Its versatility makes it a preferred choice in the automotive, electronics, consumer goods, industrial, and medical sectors. With its superior processability and durability, ABS AE10EP continues to be a reliable material for manufacturers seeking high-quality thermoplastic solutions.

By understanding the key properties and applications of ABS AE10EP, industries can leverage its advantages to create innovative and high-performance products. Whether in automotive parts, consumer electronics, or industrial components, ABS AE10EP remains a go-to material for applications requiring strength, reliability, and superior aesthetics.