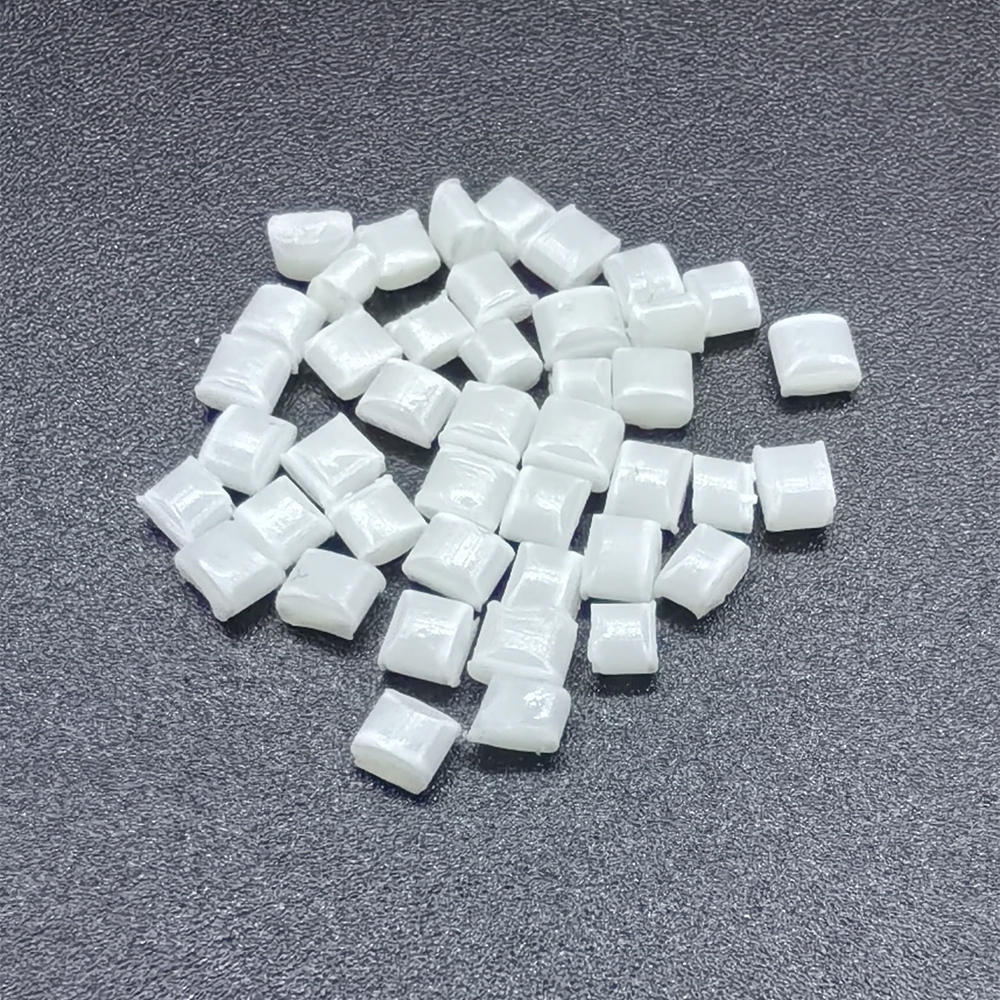

ABS AE8000

Types:ABS

Model:AE8000

Manufacturer:25KG/Bag

Specification:Formosa Chemicals & Fibre Corporation

Color:Natural / Black

Shipping Location:Dongguan City, Guangdong Province, China

Email:Max@abs-Plastic.com

Phone:86+ 13790282186

WeChat:13790282186

Click me to view prices

Introduction to ABS AE8000 Material: Properties and Applications

Acrylonitrile Butadiene Styrene (ABS) is one of the most widely used engineering thermoplastics due to its excellent balance of strength, toughness, and ease of processing. ABS AE8000 is a specialized grade of ABS designed to offer enhanced performance in various applications. This material stands out due to its impressive combination of physical properties, including high impact resistance, chemical stability, and ease of processing, making it ideal for a wide range of industries. In this article, we will explore the key properties of ABS AE8000 and its various applications across multiple sectors.

Key Properties of ABS AE8000

ABS AE8000 is specifically engineered to meet the demands of industries that require superior mechanical properties and reliability. This material offers the following critical features:

1. Impact Resistance

One of the most notable features of ABS AE8000 is its exceptional impact resistance. This property allows ABS AE8000 to withstand mechanical stress and physical impacts without cracking or breaking. Whether used in household appliances, automotive components, or electronics housings, ABS AE8000 offers high durability and robustness. This makes it an ideal material for applications where the product might be subjected to shock, drop, or accidental collision.

2. Chemical Resistance

ABS AE8000 is highly resistant to a broad range of chemicals, including oils, acids, alkalis, and organic solvents. This chemical resistance ensures that the material maintains its integrity and does not degrade when exposed to harsh environments. This feature is particularly useful in applications where the material is exposed to chemical substances or requires resistance to environmental factors that could cause traditional plastics to degrade. The ability to resist corrosion and chemical attack extends the product’s lifespan and reduces maintenance costs.

3. Thermal Stability

ABS AE8000 offers good thermal stability, allowing it to perform effectively in a wide temperature range. Typically, it can withstand temperatures from -20°C to 80°C, which is essential for applications that experience fluctuating or extreme temperatures. This thermal stability ensures that ABS AE8000 maintains its physical properties and dimensional integrity under various temperature conditions, making it suitable for both indoor and outdoor applications.

4. Dimensional Stability

ABS AE8000 has excellent dimensional stability, which means it retains its shape and size even when subjected to environmental changes such as temperature fluctuations or humidity. This is an important property, especially in applications where precision and accuracy are required. ABS AE8000 ensures that molded components will not deform or shrink during or after the production process, resulting in parts that are uniform and fit well within assembly lines.

5. Surface Finish and Aesthetic Quality

Another significant advantage of ABS AE8000 is its smooth surface finish. The material can achieve a polished, glossy appearance that is ideal for consumer-facing products. This is particularly valuable for industries where both functional durability and visual aesthetics are important, such as in electronics and automotive applications. Additionally, ABS AE8000 can be easily painted, coated, or printed on, which further enhances its versatility for various design requirements.

6. Ease of Processing

ABS AE8000 is known for its ease of processing, which makes it well-suited for high-volume manufacturing. The material can be processed using common techniques like injection molding, extrusion, and thermoforming. These processing capabilities enable manufacturers to produce complex, intricate parts with high precision and minimal waste. The ease of processing also makes ABS AE8000 a cost-effective option for large-scale production runs, as it helps to reduce processing time and labor costs.

Applications of ABS AE8000

Due to its superior combination of physical properties, ABS AE8000 is used in a wide range of applications across various industries. Below are some of the primary sectors that benefit from the unique properties of ABS AE8000:

1. Automotive Industry

ABS AE8000 plays a crucial role in the automotive industry, where its impact resistance and chemical stability are highly valued. The material is used in the manufacturing of exterior and interior automotive components, such as:

- Bumpers and panels: ABS AE8000’s ability to absorb shocks and impacts makes it ideal for producing bumpers and body panels.

- Dashboard components: The smooth surface and chemical resistance make ABS AE8000 suitable for creating durable and aesthetically pleasing dashboard parts.

- Trim and moldings: ABS AE8000 is also used for producing trims, moldings, and other cosmetic components within vehicle interiors, where both function and appearance are important.

These applications benefit from the material’s dimensional stability, ensuring parts maintain their integrity even under harsh environmental conditions.

2. Consumer Electronics

In the consumer electronics industry, ABS AE8000 is frequently used for the production of housings and casings for devices like:

- Smartphones and tablets: ABS AE8000 is utilized to create strong yet lightweight casings that can withstand daily handling and minor impacts.

- Laptops and monitors: The material is used in the casings of laptops, desktop computers, and other electronics, where both durability and a sleek surface finish are required.

- Home appliances: ABS AE8000 is used for a range of consumer home appliances, including vacuum cleaners, air conditioners, and coffee machines, where heat resistance and aesthetic qualities are crucial.

ABS AE8000’s ability to maintain surface quality while offering robust protection for sensitive internal components makes it a popular choice in consumer electronics.

3. Industrial Equipment

ABS AE8000 is also commonly used in the industrial equipment sector, where its chemical resistance and impact strength are essential. It is often used for the production of:

- Protective enclosures: ABS AE8000 is employed for protective housings and enclosures for industrial equipment, ensuring safety and protection for sensitive machinery.

- Machine parts: ABS AE8000 is used in the production of non-structural parts of machinery, such as covers, panels, and control buttons, where toughness and resistance to chemicals are required.

These applications take advantage of ABS AE8000’s durability, chemical resistance, and ease of processing.

4. Household Goods

In the household goods sector, ABS AE8000 is used for a variety of products that require both strength and aesthetic appeal, such as:

- Kitchen appliances: ABS AE8000 is used in the housings of products like mixers, blenders, and refrigerators, where impact resistance and thermal stability are needed.

- Toys: ABS AE8000 is also used in the production of durable and safe toys, where it must withstand heavy usage and occasional rough handling.

5. Pipes and Fittings

The material’s chemical resistance makes it a great choice for the production of pipes, fittings, and other plumbing components. ABS AE8000 is used in both residential and industrial applications where it is exposed to a wide range of chemicals, ensuring reliable performance and long-lasting durability.

Conclusion

ABS AE8000 is a high-performance thermoplastic that offers a range of valuable properties, including impact resistance, chemical resistance, thermal stability, and surface finish quality. These properties make it an ideal material for various applications, from automotive and consumer electronics to industrial equipment and household products. Its ease of processing further enhances its appeal for large-scale manufacturing, making it a cost-effective solution for many industries. As industries continue to demand materials that combine performance, durability, and aesthetic qualities, ABS AE8000 remains a top choice for manufacturers worldwide.