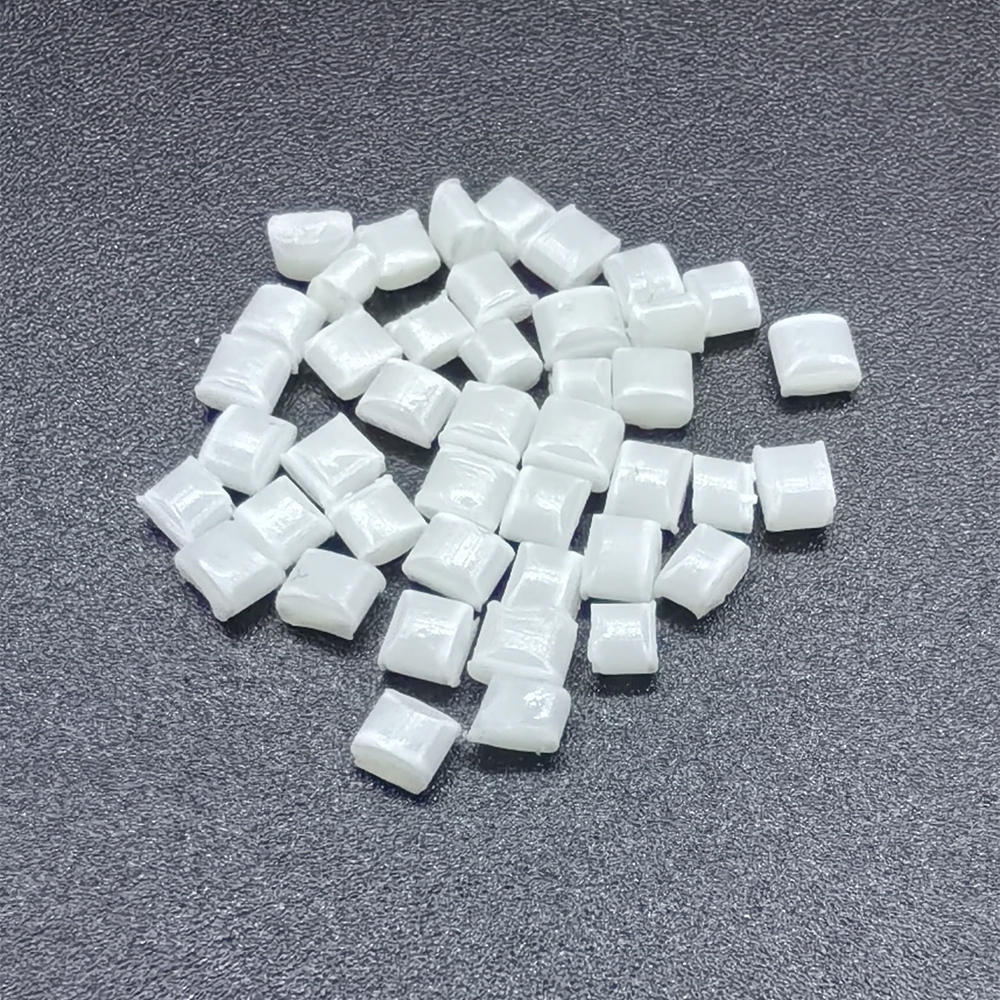

ABS AF3500

Types:ABS

Model:AF3500

Manufacturer:25KG/Bag

Specification:Formosa Chemicals & Fibre Corporation

Color:Natural / Black

Shipping Location:Dongguan City, Guangdong Province, China

Email:Max@abs-Plastic.com

Phone:86+ 13790282186

WeChat:13790282186

Click me to view prices

Introduction to ABS AF3500 Material: Properties and Applications

Acrylonitrile Butadiene Styrene (ABS) is a popular thermoplastic polymer known for its robust mechanical properties, versatility, and ease of processing. One specific grade, ABS AF3500, is particularly valued for its balanced combination of strength, durability, and resistance to environmental stressors. This material is often chosen for applications requiring impact resistance, chemical stability, and high-quality surface finishes. In this article, we will explore the properties and applications of ABS AF3500, highlighting why it has become an essential material in various industries.

Key Properties of ABS AF3500

ABS AF3500 is designed to meet the demands of high-performance applications across a range of sectors. Its advanced formulation offers several key properties that contribute to its suitability in a wide variety of industries.

1. Impact Resistance

One of the standout features of ABS AF3500 is its superior impact resistance. This property is crucial for materials used in environments where mechanical stress or external impacts are common. ABS AF3500 can absorb significant forces without cracking or breaking, which makes it an ideal choice for products that need to maintain integrity under physical stress. Whether it’s a component in the automotive industry or a casing in consumer electronics, ABS AF3500 ensures that products remain functional and reliable even after frequent exposure to impact.

2. Chemical Resistance

ABS AF3500 demonstrates excellent chemical resistance, a vital characteristic for products that will be exposed to harsh environments. The material is resistant to a variety of chemicals, including oils, solvents, and mild acids or bases, which helps prevent degradation and ensures the longevity of the final product. This makes ABS AF3500 highly suitable for use in industries like automotive manufacturing, industrial equipment, and consumer goods, where components often come into contact with various chemical substances. Its resistance to chemical corrosion allows products made from ABS AF3500 to perform reliably over extended periods.

3. Thermal Stability

ABS AF3500 is also known for its thermal stability, which enables it to perform well in a range of temperatures. The material typically maintains its mechanical properties and shape in temperatures ranging from 85°C to 95°C. This is particularly important for products used in environments where temperatures fluctuate or where high heat exposure is expected. Whether it’s used for automotive parts or consumer electronics, ABS AF3500 provides the thermal resilience needed to ensure the durability and functionality of products under diverse temperature conditions.

4. Dimensional Stability

ABS AF3500 offers excellent dimensional stability, ensuring that products maintain their shape and size even under varying temperature conditions or mechanical stress. This property is critical in industries that require high precision, as any warping or shrinkage of the material can affect the performance and fit of components. For applications where tight tolerances are necessary, such as in the automotive or electronics sectors, ABS AF3500’s ability to retain its shape over time ensures consistent performance.

5. Surface Finish

Another key advantage of ABS AF3500 is its high-quality surface finish. The material is capable of being molded into smooth, aesthetically pleasing surfaces, which is particularly important for applications where appearance plays a significant role. ABS AF3500’s smooth surface makes it easy to paint, coat, or decorate, offering flexibility for manufacturers to produce visually attractive products. From consumer electronics housings to automotive trim, ABS AF3500 provides an excellent base for creating products that are both durable and visually appealing.

6. Ease of Processing

ABS AF3500 is known for its ease of processing, which allows manufacturers to efficiently produce components using various techniques such as injection molding, extrusion, and thermoforming. This makes it a cost-effective material for high-volume production. The ease with which ABS AF3500 can be processed allows manufacturers to create intricate shapes and complex designs with minimal waste, reducing production time and costs. This property also makes it highly adaptable for use in a range of industries, from automotive to consumer goods.

Applications of ABS AF3500

The unique combination of impact resistance, chemical resistance, thermal stability, and aesthetic quality makes ABS AF3500 suitable for a wide variety of applications across different sectors. Some of the key industries and uses include:

1. Automotive Industry

In the automotive industry, ABS AF3500 is commonly used for both interior and exterior components. Its excellent impact resistance and dimensional stability make it ideal for parts that need to endure regular wear and tear while maintaining their shape and functionality. Applications in the automotive sector include:

- Bumpers and body panels: ABS AF3500’s impact resistance makes it an ideal material for manufacturing bumpers, fenders, and other body panels that must absorb impact energy without breaking.

- Dashboard components: The material is also widely used in the production of dashboards and console parts, where both aesthetic appearance and durability are essential.

- Interior trim and molding: ABS AF3500’s smooth surface finish makes it a perfect choice for interior trim and molding, adding both durability and visual appeal to the cabin.

These applications benefit from ABS AF3500’s chemical resistance, ensuring that components can withstand exposure to oils, fuel, and other automotive fluids without degrading.

2. Consumer Electronics

ABS AF3500 is highly valued in the consumer electronics industry due to its impact resistance, thermal stability, and surface finish. Common uses include:

- Smartphone and tablet housings: ABS AF3500 is used in the production of mobile device cases, where it must absorb impacts and maintain a smooth, high-quality appearance.

- Television and monitor casings: The material is also utilized in the creation of protective housings for electronic devices like TVs and monitors, where a sleek, glossy finish is essential.

- Computer peripherals: ABS AF3500 is often used for the construction of computer accessories like keyboards, mouse housings, and other peripherals.

In all these applications, ABS AF3500’s thermal stability ensures that products can function well even in high-heat environments, while its ability to maintain a pristine surface finish ensures that products remain visually appealing.

3. Industrial Equipment

In the industrial sector, ABS AF3500 is used for components that require strength, chemical resistance, and dimensional stability. Common industrial applications include:

- Enclosures and housings for machinery and electrical equipment: ABS AF3500 is used to protect sensitive components in industrial equipment from physical damage and environmental factors.

- Piping systems: The material’s chemical resistance makes it suitable for industrial piping systems that are exposed to a variety of fluids and chemicals.

- Protective covers: ABS AF3500 is often employed for creating protective covers for machines and tools, where durability and resistance to environmental stressors are essential.

ABS AF3500’s ability to resist chemicals, impacts, and temperature fluctuations makes it a reliable material for harsh industrial environments.

4. Household Appliances

In the household appliance industry, ABS AF3500 is used for components that need to withstand frequent use, temperature changes, and exposure to cleaning agents. Applications include:

- Refrigerator panels and parts: ABS AF3500’s chemical resistance and dimensional stability make it an ideal choice for refrigerator interiors and external panels.

- Microwave housings: ABS AF3500 is often used for microwave oven housings, where heat resistance and durability are necessary.

- Vacuum cleaner parts: The material is commonly found in vacuum cleaner bodies and parts, where impact resistance and strength are critical.

These applications benefit from the material’s ability to maintain its appearance and performance over time, even with frequent use.

Conclusion

ABS AF3500 is a high-performance thermoplastic material known for its outstanding impact resistance, chemical resistance, thermal stability, and high-quality surface finish. These properties make it a preferred material for a broad range of applications, from automotive and consumer electronics to industrial equipment and household appliances. ABS AF3500’s ease of processing and dimensional stability further enhance its appeal, allowing for efficient production of reliable, high-quality products. As industries continue to demand versatile and durable materials, ABS AF3500 remains a top choice for manufacturers seeking a material that can meet both functional and aesthetic requirements across a variety of applications.