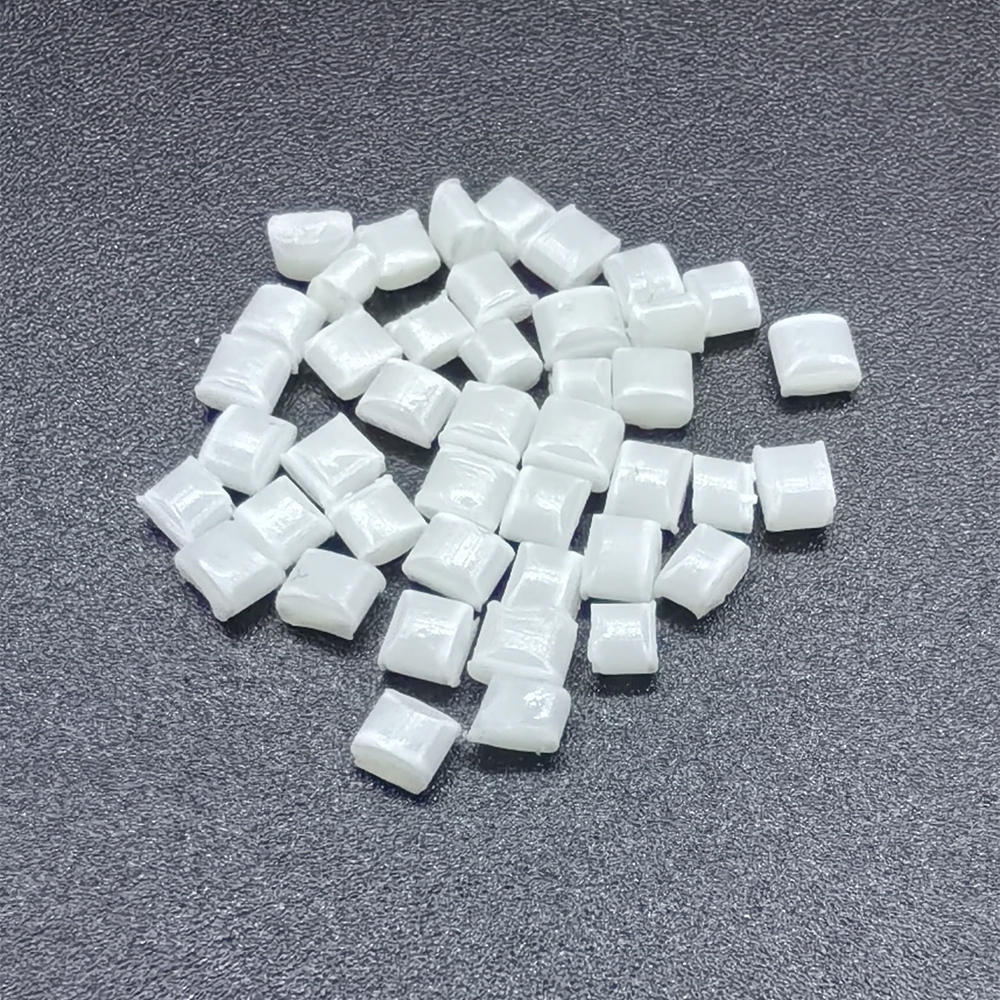

ABS AF3560

Types:ABS

Model:AF3560

Manufacturer:25KG/Bag

Specification:Formosa Chemicals & Fibre Corporation

Color:Natural / Black

Shipping Location:Dongguan City, Guangdong Province, China

Email:Max@abs-Plastic.com

Phone:86+ 13790282186

WeChat:13790282186

Click me to view prices

Introduction to ABS AF3560 Material: Properties and Applications

ABS (Acrylonitrile Butadiene Styrene) is one of the most widely used thermoplastic polymers in the world, appreciated for its versatility, toughness, and ease of processing. ABS AF3560 is a specialized grade of ABS designed to meet the rigorous demands of modern industries. It is particularly known for its outstanding performance in terms of impact resistance, thermal stability, and chemical resistance, making it ideal for various applications where durability and reliability are crucial. This article provides an overview of the key properties of ABS AF3560 and highlights its primary uses across different industries.

Key Properties of ABS AF3560

ABS AF3560 is characterized by a unique combination of mechanical and physical properties that make it suitable for a wide range of applications. These properties include strength, resilience, thermal stability, and aesthetic quality.

1. Impact Resistance

One of the standout features of ABS AF3560 is its high impact resistance. The material is designed to absorb shocks and mechanical stress effectively, making it ideal for environments where parts are likely to face sudden impacts or heavy wear. This property is crucial in industries such as automotive, electronics, and consumer goods, where product durability is of utmost importance. ABS AF3560’s toughness ensures that components remain intact even under severe conditions, reducing the likelihood of cracks or breakage.

2. Chemical Resistance

ABS AF3560 exhibits strong chemical resistance, allowing it to perform well in environments where exposure to oils, solvents, acids, and bases is common. This property makes it an excellent choice for applications in industries such as automotive, chemical processing, and electrical equipment where components may come into contact with harsh chemicals or fluids. The material’s ability to resist degradation from chemicals ensures a longer lifespan for the products made from it, contributing to lower maintenance costs and increased reliability.

3. Thermal Stability

ABS AF3560 offers good thermal stability, meaning it can withstand a range of temperatures without losing its structural integrity or mechanical properties. While it may not be suitable for extreme heat conditions like some high-performance engineering plastics, ABS AF3560 can endure moderate to high temperatures (typically between 85-95°C), making it a reliable choice for products that will be exposed to temperature fluctuations. This thermal stability ensures that ABS AF3560 parts maintain their form and functionality, even in hot or cold environments.

4. Dimensional Stability

ABS AF3560 provides excellent dimensional stability, meaning that it retains its shape even after prolonged exposure to stress, temperature changes, or humidity. This feature is critical in applications where precise dimensions are important. For example, in the automotive industry, where parts need to fit together perfectly for both aesthetic and functional reasons, ABS AF3560’s stability ensures that components stay in place and perform consistently over time.

5. Aesthetic Quality

In addition to its mechanical properties, ABS AF3560 offers a smooth and glossy surface finish, which is essential for applications where appearance matters. The material can be easily painted, coated, or decorated, which makes it ideal for products that require a high-quality visual appearance. Its ability to maintain a glossy, smooth finish makes it a popular choice for consumer-facing applications, where both functionality and aesthetics are important.

6. Ease of Processing

ABS AF3560 is relatively easy to process, making it an efficient material for large-scale production. The material can be molded, extruded, and thermoformed, which allows manufacturers to create a wide variety of shapes and sizes with high precision. Its ease of processing reduces manufacturing time and costs, while its consistency in production ensures that each component is of high quality. This makes ABS AF3560 an attractive option for industries that require mass production of complex parts.

Applications of ABS AF3560

ABS AF3560’s superior mechanical properties and versatility make it suitable for a broad range of industries and applications. Below are some key sectors where ABS AF3560 is commonly used:

1. Automotive Industry

In the automotive industry, ABS AF3560 is often used for interior and exterior parts due to its impact resistance and dimensional stability. Some common automotive applications of ABS AF3560 include:

- Bumpers, grilles, and exterior body panels, which require high impact resistance to protect vehicles from minor collisions.

- Dashboard components, center consoles, and door trims, where a smooth finish and aesthetic appeal are equally important alongside durability.

- Housing for automotive electronics such as light assemblies and sensor enclosures, where both thermal stability and chemical resistance are necessary.

The strength and resilience of ABS AF3560 ensure that automotive parts remain functional and visually appealing for long periods, even under challenging conditions.

2. Consumer Electronics

ABS AF3560 is extensively used in the consumer electronics industry, particularly for manufacturing enclosures and components that require a balance of toughness and aesthetics. Typical consumer electronics applications include:

- Smartphone housings, tablet cases, and laptop covers, where the material must provide impact resistance while offering a sleek, high-quality finish.

- TV frames, audio equipment enclosures, and home appliance parts, where durability and visual appeal are key factors for both function and consumer satisfaction.

- Peripheral devices, such as keyboard casings and mouse shells, which require dimensional stability and a smooth surface for easy handling.

In the consumer electronics sector, ABS AF3560’s combination of performance and appearance ensures that devices are not only durable but also maintain a premium look.

3. Industrial Applications

ABS AF3560’s chemical resistance and strength make it ideal for industrial applications, particularly in environments where exposure to chemicals or harsh conditions is common. Some typical industrial applications of ABS AF3560 include:

- Protective covers for electrical equipment and control panels, which must be resistant to chemical exposure and physical impact.

- Piping components, valves, and containers used in the chemical processing and oil and gas industries, where material integrity is vital for safe and efficient operation.

- Industrial tools and machinery housings that need to withstand both mechanical stress and chemical contact.

In industrial settings, ABS AF3560’s resilience and stability ensure reliable performance even in demanding environments.

4. Household Appliances

In the household appliance industry, ABS AF3560 is used to create components that require both high strength and aesthetic appeal. Some common applications include:

- Microwave housings, vacuum cleaner bodies, and refrigerator panels, where the material needs to withstand daily wear and exposure to high temperatures and cleaning agents.

- Washing machine parts, dishwasher components, and coffee maker bodies, where chemical resistance and impact resistance are critical to maintaining functionality over time.

ABS AF3560’s thermal stability and impact resistance ensure that household appliances remain operational and aesthetically pleasing for extended periods.

Conclusion

ABS AF3560 is a versatile and high-performance material that offers a unique combination of impact resistance, chemical stability, thermal stability, and aesthetic quality. Its ability to withstand harsh conditions while maintaining high performance and appearance makes it suitable for a wide range of applications across various industries, including automotive, consumer electronics, industrial manufacturing, and household appliances. The material’s ease of processing and reliability ensure that products made from ABS AF3560 are not only durable but also cost-effective, contributing to their continued popularity in modern manufacturing.